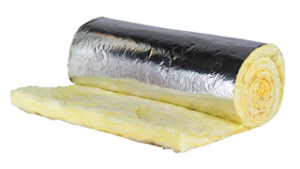

GLASSWOOL

- It is formed by melting silica sand, which is an inorganic raw material supplied locally, at 1200ºC – 1250ºC and turning it into fiber.

- It can be produced in different sizes and technical specifications, with different coating materials, in the form of mattresses, plates, pipes and casts according to the place and purpose of use.

- It provides thermal insulation, sound insulation and acoustic regulation as well as fire safety.

- Thermal conductivity declaration value is λ≤0,040/mK.

- Water vapor diffusion resistance factor µ=1.

- Use temperature is in the range of -50 / +250ºC. Glass wool products without binder can be used up to 500°C. In addition, special glass wool products used in the -200 / +400ºC range can also be produced.

- Even if it is exposed to heat and humidity, there is no change in its dimensions.

- It does not deteriorate, rot, mold, corrosion and rust over time. It is not destroyed by insects and microorganisms.

- It is not hygroscopic and capillary.

- According to the German Norm DIN 4102 and Turkish Standard TS EN 13501-1, it is in class A, which is “fireproof materials”.

ROCKWOOL

- It is formed as a result of melting basalt stone, which is a domestically supplied inorganic raw material, at 1350°C-1400°C and turning it into fiber.

- Depending on the place and purpose of use, it can be produced in different sizes and technical specifications, with different coating materials, in the form of mattresses, plates, pipes and bulk.

- It is used for thermal insulation, sound insulation, acoustic regulation and fire insulation.

- Thermal conductivity declaration value is λ≤ 0,040 W/mK.

- Water vapor diffusion resistance factor µ=1.

- Use temperature is in the range of -50/+600, -50/+650°C.

- Even if exposed to heat and humidity, there is no change in its dimensions.

- It does not deteriorate, rot, mold, corrode or rust over time. It cannot be destroyed by insects and microorganisms.

- It is not hygroscopic and capillary.

- According to TS EN 13501-1, it is in class A, which is “fireproof materials”.

XPS

- It is produced by extrusion from polystyrene raw material.

- It can be produced in different sizes and compressive strengths, in different rhombic and surface shapes according to the place and purpose of use.

- It is used for thermal insulation purposes.

- Thermal conductivity declaration value λ ≤ 0,035 W/mK.

- Water vapor diffusion resistance factor µ=90-100.

- Use temperature is in the range of -50/+75ºC.

- It has a 100% closed pore homogeneous cell structure and does not absorb water.

- No capillary absorbency.

- Compressive strength is very high.

- It is in class E according to TS EN 13501-1.

EPS

- The raw material of Expanded Polystyrene rigid foam used for insulation and decorative purposes in the construction industry is petroleum.

- The material is obtained by inflating polystyrene particles and replacing pentane gas with air. 98% of the material consists of stagnant air trapped in small porous cells. The replacement of pentane gas with air causes the performance of the product to stabilize. Thus, basic values such as thickness and conductivity never change.

- Thanks to its superior properties, EPS is one of the best, economical and environmentally friendly insulation materials known.

- Expanded Polystyrene boards, which are used in insulation and provide high performance, are very light and do not affect the static weight of the building. As the density of the boards increases, the insulation rate increases.

- Produced in different densities, EPS has a wide range of uses due to its advantages.